EH1

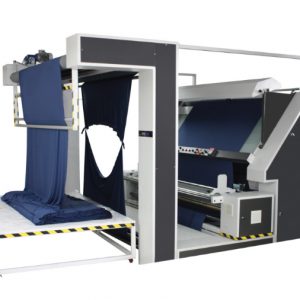

Open Width Knitted Fabric Inspection Machine By Air

Inspection machines are used for reviewing and testing of fabrics in order to detect and eventually register weave faults, stains or mechanical faults. To facilitate review of fabrics the machine have a backlighted screen with glass surface the fabric goes above. The fabric can be winded and rewinded and they also allow to measure length of fabric which went through the machine. Inspection machines are used in production companies, where high quality of the finished product force an additional quality control of fabrics before cutting them.

DESIGNED FOR REWIEVING, REWINDING AND LENGTH MEASUREMENT OF ALL KIND OF KNITTED FABRICS (DYED OR GREY) PERFECT ROLLING WITHOUT TENSION AND AIR BLOWING SYSTEM

TECHNICAL FEATURES

√ Has upper UV lighting from the top & lower illumination panel (white fluorescent light) including with measuring device

√ Inspection glass made of natural glass prevents from static charges induction during rewinding

√ Provides easy operation with photocell stop when the end of the fabric is reached

√ Edge alignment photocells to keep fabrics rolled up with even edge

√ Automatic tension control for accurate fabric winding

√ System of reels with helix-shaped spirals continuously prevents from ruffling and rolling of fabric during rewinding

and assures fabric straightening

√ Additıonal UV light (except white light) assures better visibility of faults

√ Easy and ergonomic usage – all control switches are in front of the operator

√ Precise measurement of fabric length due to large reels equipped with an electronic encoder, which are turning

together with reviewed fabric

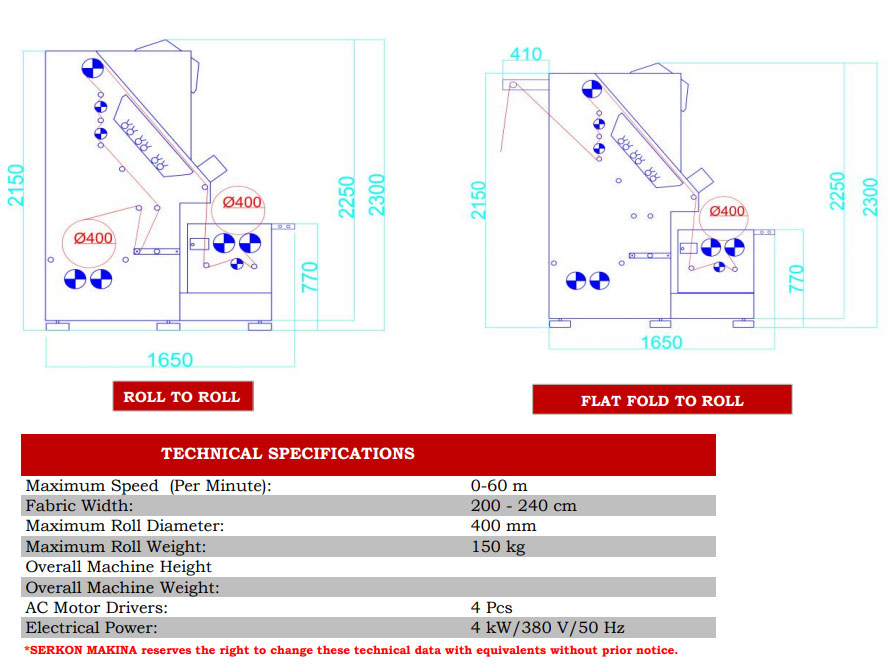

Technical Properties