MN1 MINI MASTER

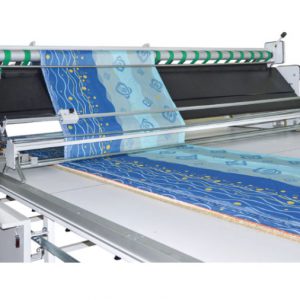

Light Weight Fabric Automatic Spreading Machine

Automatic spreading machine allows spreading of a full range of available fabrics: from very delicate, thin, elastic and difficult to spread, to thick, heavy fabrics like jeans. The machine is equipped with a cradle with belt feeding, driven all spreader wheels, operator’s platform and easy to use touchscreen MN1 spreading machine is available in different max. Working widths ranging from 150-260 cm.

MAIN ADVANTAGES OF MINI MASTER [MN1] USAGE

- Elimination of manual spreading and layering of fabrics which is the weakest part of the cutting room production chain

- Several times increase of spreading efficiency for each type of fabric

- Only one operator results in significant reduction of work costs

- Very fast spreading of mattresses for small series and single production orders

- Constant quality of spreading independent of length of spread marker with elimination of fabric tensioning in different

layers what’s a typical problem for manual spreading - Easy and intuitive operation, possible also for not-qualified personal

- Perfect reliability of operator assures continuous production and lowest possible costs of maintenance

- Fast and solid service assured by experienced technicians

OPERATIONAL SPECIFICATIONS OF MINI MASTER [MN1]

√ CRF – Cradle feed with a system of feeding belts assuring easy loading and unloading of fabric rolls

√ AEC – Automatic alignment of fabric edge of all spread fabric layers

√ STD – Spreading of fabrics in standard system (right side up with transversal cutting)

√ ZZG – Set of front and end catchers allowing zig-zag spreading (left side to right side)

√ IFS – Intelligent fabric feeding system with dynamic measurement of fabric tension during spreading

gives the possibility to control fabric tension

√ NTF – Non-Tension Feeding – tensionless feeding and spreading of fabric

√ Easy inversion of spreading side (right side up or left side up)

√ Automatic re-winding (feeding and rolling back) with fabric edge alignment

√ Automatic stop of the machine when fabric is finished with audible signal

√ Programmable shifting points allows for fast cutting of the places with faults and continuation of work

√ Software calculates length of spread fabric with reporting of fabric usage

√ ARC – Automatic one-side cutting of fabric by a transversal cutting unit with rotary blade

√ ACL – Automatic adjustment of cutting unit slat to height of currently spread height of layers

√ ODP – Movable operator platform [which can be closed and locked] facilitates usage and assures

highest possible spreading speed

√ TFT – Color touchscreen (LG) assures easy and comfortable adjustments of working parameters

√ 10PR – Possibility to store in memory of the touchscreen up to 10 parameter profiles for different fabrics

√ ASS – Automatic stoppage of machine’s movement after approaching to an obstacle assures safety of

operator and other personnel which could stand close to the machine

√ Seamless cradle feed belt instead of slit belts assures that no fabric edge will go under it

√ Available with different types of spreading tables – most commonly used are 18mm

Light tables with or without air flotation system & Conveyorized tables

MAIN SPECIFICATIONS

Machine Model: Mini Master [MN1]

Machine Name: Fully Automatic Fabric Spreading Machine

Material Use: Fabrics such as Woven, knit, jeans, Full Lycra, etc.

Fabric Width: 000 cm

Roll Diameter: 450 mm max

Machine Speed: 0-100 mt/min with speed control (depends on fabric style)

Spreading Height: 230 mm Maximum with cutting Unit / 220 mm Maximum with zig zag spreading height /

200 mm Maximum with tubular unit

Fabric Weight: 120 kg max.

Loading Fabric: Easy load

Main Spreading Motor: 0.75 kW 1500 Rpm AC Motor with Gearbox (PGR Drive Technologies)

Cradle Left-Right: 0.18 kW 1500 Rpm AC Motor with Gearbox (WAT)

Cradle Feed: 0.75 kW 3000 Rpm AC Motor with Gearbox (PGR Drive Technologies)

Lift Motor: 0.19 kW 24V DC Motor with Gearbox (KORMAS)

Fabric Edge Cutter: Clack Motor (24V DC),Knife transfer motor (24V DC) with gearbox, Knife Rotate (24V DC) (Kormas)

Control Modes: Automatic or Manuel control

Edge Control: Edge control with 2 Photocells

No Cloth Stop Funct: Automatic stop with 1 photocell control when fabric is over

Safety Device: 2 security photocells to stop the machine if someone step in front/rear side of the machine.

Height Photocell: A photocell which moves lift while spreading height goes up

Electronic System: Special software with LG PLC

Control System: LG 5,7 inch Touch Screen

Drivers: 2 LG Invertors

Settings From Control Panel

√ Level count √ Spreading Length √ Spreading Speed (forward and backward) √ Tension Settings

√ Using with Password √ Zigzag or One way Selection √ Tension Setting at Start or Stop

√ Disabling Security Sensor if Needed √ Disabling Fabric Over Sensor if Needed

Machine Dimensions:

Machine Weight:

Installed Power: 5 kW 220 volt

Attachments: Automatic cutting device & Movable catcher [standard]

Paint: Main with electrostatic paint, covers with wet paint

Operator Platform: Allows operator to ride alongside the table

Spreading Table:

Table Length: 00 Meter

Table Width: 000 cm. Special construction that can be used with MN1 Spreading Machine

Table Electric System: EAE Busbar System

Paint: Electrostatic Paint

Table Height: Between 840-870 mm

Rail System: Enable for MN1 Spreading Machine and its platform

Technical Properties